The Ditty Bag Book

by Frank Rosenow

ISBN 0-914814-05-2 76-4286 623.862 76.1 cop.2

published in 1976 by Sail Books, Inc, 38 Commercial Wharf, Boston, MA

The Tools

Few things on board a boat afford its owner or crew as much satisfaction as

keeping a trim craft in rope, rigging, and sails. To achieve this, the sailor

of yore carried a cotton duck ditty bag with a carefully selected assortment of

tools that enabled him, in substantial measure, to render the same

services to his vessel as a full-blown sailmaker or rigger. The contents of the

ditty bag also served as a darning kit for his wardrobe, and as a source

of materials for practicing decorative knotting and other seafaring arts. As

such objectives are as legitimate and necessary on the cruising or racing

sailboat of today, or can be undertaken for the sheer pleasure of it in some

land-bound nook, I will here make an inventory of the traditional tools—with

some additions prompted by technological advances and the reign of synthetic

materials—that you will find of use in all manner of canvas (including Dacron

and nylon) and rope work on board.\

The Sailmaker/s Bench

There is no denying that the ditty bag concept owes its tools and methodology in

large measure to professional sailmakers and, to a lesser extent, riggers. Let

us therefore begin with a passing glance at a right-handed sailmaker's bench and

see how it is professionally utilized, even though it is unlikely

that this particular tool will fit into your fo'c's'le, let alone the ditty bag.

The right-handed sailmaker's bench shown in Fig. 1 (for a left-hander, the bench

ends and work direction would have to be mirrored) is designed mainly

for hand seaming, but since its occupant has a wide selection of tools within

easy reach, the wooden bench can be adapted to every phase of traditional

sailmaking—except panel cutting, which is most conveniently done on the floor.

Benches employed in landlocked lofts are recognized by their straight

legs, while a seagoing bench spreads its legs wide for stability as befits a

nautical character.

The most comfortable height of the bench or the more compact sewing stool (an

alternative for on-board use if fitted with an attachment point for a sailhook

lanyard, a couple of holes for fids, and a- shelf or canvas bag for oddments) of

course will depend on the length of your own legs. I am six feet

tall with legs to match and work comfortably on the 15"-high bench in the

drawing. This may seem low, but there is a reason for it, as we shall see.

But try it out for yourself. You're sitting on a cushion which can slide along

the 6'-long bench. On your right, there's a small, holed shelf to hold

the fid collection, and a pin around which the roll of seaming twine can

revolve. Nestled in just beside you to the right is a 10" X 16" area bordered

by a 1" rim. In this cozy nook, which was referred to as the "cow pasture" when

I was apprenticed, you can leave your palm and needles (stuck into a

soft felt pad where they are readily at hand), along with clew rings, beeswax,

knife, thimbles, and the half-dozen other items you'll want within

arm's reach. At the far outside corner, the pasture is overlooked by a 20"-high

post (actually an extension of one leg) which has a sail-hook and lanyard

twisted round the top. Some benches, notably in the U.S., lack this post, the

sailmaker simply looping the lanyard through a hole, instead.

Our man on the job in Fig. 2 demonstrates the hook's use. He is in the

process of flat-seaming, joining two cloth panels which he has tucked in and

overlapped

at the edge to prevent fraying. The sailmaker's hook is inserted at the seam,

enabling him to tension the cloth with his left hand while taking stitches

with his right. The lower cloth is doubled back so that left-handed tension can

be applied near to where the stitches are being taken. The work piece is draped

over his knees and, when positioned correctly, his

upper body is nearly at a right angle to the seam, with stitches being taken in

the vicinity of his right thigh. This is the reason for the low bench—it

elevates the knee to a position where a workpiece resting on it is within

comfortable reach.

If you look closely, you may also be able to see that our sailmaker is using a

roping palm. To heave home a stitch properly, he has let the needle slip

out of the iron and under his ring finger, so that he can take a turn of twine

around the thumb guard and pull tight on the stitch. As the seam progresses,

he'll slide down along the bench on his cushion, unlaying the sailhook lanyard

from the post from time to time to reinsert the hook closer to where he is

stitching, thus lending stability to the work.

Clasp Knife

A sailmaker's or bosun's principal rope and canvas tool—a stubby, broad-bladed

knife—would be carried strapped to his back, where he could reach it with either

hand when aloft. More often than not it was homemade. I recall, for instance, a

fine-looking Norwegian sailor's knife which bears the inscription: "Laget av

seilmaker Halvorsen av en saks i Australia 1900." ("Fashioned in 1900 from a

pair of Australian scissors by sailmaker Halvorsen.")

However, for the purpose of this sample inventory of a functional, present-day

ditty bag, I prefer to break with such homespun tradition and introduce a

smaller, more versatile type of knife. For the first and foremost ditty bag

tool, then, look for a handy clasp knife with a non-corroding blade. I use one

with a 3" blade (Fig. 3) made of hardened Swedish cutting-edge steel which

reaches excellent sharpness. A larger variety (Fig. 4) might have a 4" blade, a

catch to lock the blade in exposed position, and a hole for fitting a lanyard,

and thus be more suitable for general use above and beyond ditty bag chores. All

you really need for canvas and rope work, though, is one high-quality blade and

a comfortable

handle in wood or plastic. A sharp, thin blade will make it a simple matter to

cut sailcloth along warp or fill, or even on the bias if you have a penciled

guideline. When cutting canvas (or, of course, its synthetic counterpart),

spread the workpiece flat on a floor or clear deck space, tensioning the section

to be cut with your left hand and/or knees and elbows. Do not cut from the top

downward, but rather from under the canvas, with the knife blade pointed up.

There are those who use scissors in canvas work, but there is little a really

sharp knife can't do as well, and with greater versatility.

Sharpening Stone

Many of these stones feature a rough side and a smooth side, so that they can

first be used to "rough-sharpen" a dull edge, then turned over and applied to

the task of really producing a fine, relatively burr-free edge. The edge thus

achieved satisfies most needs, but for the stickler who wants to go all the way,

there is soft and hard Arkansas oilstone, quarried from novaculite deposits near

Hot Springs. These super-smooth stones are a delight to handle, and with a final

burnish on the hard stone's jet-black surface deliver the finest edge possible

(short of leather strapping in the old barbershop style). But for the general

purposes of the ditty bag, keeping a stone handy so that you can give the blade

of your knife a quick honing from dull to sharp whenever you feel it lacks bite,

I would settle for a two-sided Carborundum stone measuring at least I1//' X

3"—and preferably a bit more. Novaculite is mainly for "finishing" an already

sharp surface.

To sharpen a knife, hold the blade parallel to one end of the stone and "slice"

across the length of the stone, applying firm but not forced downward pressure

from the heel of the blade to the tip. Do this in only one direction, away from

the body for one side of the blade, and toward the body for the other side. The

blade should be kept at about a 20° angle to the stone (Fig. 5). The knife

should be turned over on alternate strokes or at short intervals so that the

blade is sharpened equally on both sides.

The chore is made easier by a few drops of lubricant on the surface of the

stone, either light, sewing machine type oil or just plain water. If the pores

of the stone still become clogged with fine grit and/or dried oil residue, give

it a thorough wash-out with gasoline.

Seaming Implements

Sailmaker's needles for a' from #4 (extra large) to with Standard Wire Gauging to the thickness of the making is a British tradition ate from England. I

find a fancy fish line knotting, b work on a sailboat, only si have to be

considered.

Sharpening stones come in diverse materials, sizes, and shapes. Today, the

most common variety is a man-made synthetic, usually Carborundum. Many of

these stones feature a rough side and a smooth side, so that they can first

be used to "rough-sharpen" a dull edge, then turned over and applied to the

task of really producing a fine, relatively burr-free edge.

The edge thus achieved satisfies most needs, but for the stickler who wants

to go all the way, there is soft and hard Arkansas oilstone, quarried from

novaculite deposits near Hot Springs. These super-smooth stones are a delight

to handle, and with a final burnish on the hard stone's jet-black surface

deliver the finest edge possible (short of leather strapping in the old

barbershop style). But for the general purposes of the ditty bag, keeping a

stone handy so that you can give the blade of your knife a quick honing from

dull to sharp whenever you feel it lacks bite, I would settle for a two-sided

Carborundum stone measuring at least 1%" X 3"—and preferably a bit more.

Novaculite is mainly for "finishing" an already sharp surface.

To sharpen a knife, hold the blade parallel to one end of the stone and

"slice" across the length of the stone, applying firm but not forced downward

pressure from the heel of the blade to the tip. Do this in only one

direction, away from the body for one side of the blade, and toward the body

for the other side. The blade should be kept at about a 20° angle to the

stone (Fig. 5). The knife should be turned over on alternate strokes or at

short intervals so that the blade is sharpened equally on both sides.

The chore is made easier by a few drops of lubricant on the surface of the

stone, either light, sewing machine type oil or just plain water. If the

pores of the stone still become clogged with fine grit and/or dried oil

residue, give it a thorough wash-out with gasoline.

Seaming Implements Needles

Sailmaker's needles for a variety of canvas work come in sizes from #4 (extra

large) to #18 (extra small), in accordance with Standard Wire Gauge

classification—the number relating to the thickness of the round part of the

needle. Needle-making is a British tradition, and the finest of them still

originate from England. I find a #12 useful for guiding the line in fancy

fishline knotting, but for regular seaming and rope work on a sailboat, only

sizes from #14:/2 through #18 will have to be considered.

A #14% needle (this is the sole half-size in the series) is appropriate for sewn

rings and other heavy-duty seaming, such as sewing a bolt rope to sails.

A #15 functions well in corner stitching through several layers of cloth, and a

#16 for stitching together two medium-weight cloth pieces. For light Dacron or

duck, a # 17 might be best, while nylon spinnaker cloth usually warrants nothing

larger than a #18. But doubtlessly you'll form your own preferences

as you go along.

A pointed, triangular section is invariably found in the cutting portion of the

needle. There are two variations on this characteristic. The "Short Square" or "Lolley"

(after English needlesmith William Lolley) is designed

for use with round, firm-lay twine and consequently has a rather pronounced eye

and a comparatively large cutting triangle to create enough of an opening

for the threaded eye to pass through without difficulty (Fig. 6). This needle is

often selected for decorative stitching, which firm twine makes more

distinctive.

"Long Square" needles have a finer taper or "reduced edge" in the cutting

section and feature an extended shank that ends in a well integrated eye (Fig.

7). This type of needle is excellent for pre-waxed or other flat or soft-lay

twine, which pulls down neatly around the eye and does not require a hole much

larger than the diameter of the shank to pass through.

For general seaming work, to my mind the best combination is a reduced-edge

needle with soft or flat twine which flows through the canvas with a minimum

of resistance. I also prefer the Long Square from the point of view that the

long shank seems to further a quick, accurate aim when spacing the stitching.

Needles are usually distributed in lots of 25 wrapped up in brown paper

envelopes (Fig. 8) with an inner wax paper lining to prevent moisture from

entering. Needle rust is a problem, especially on shipboard. The needles are

made of polished, cast steel and moisture affects them almost immediately. If

you allow any surface blemish to develop, the needle will of course become more

difficult to sew with, on account of the increased friction. Another storage

problem is that the fine points of the needles are easily blunted if knocked

around.

The sailor of old usually kept his needle-collection in a horn or tube filled

with evil-smelling tallow. I would rather recommend smearing an empty tobacco

box (Fig. 9) or some-such tin container with Vaseline and dropping in the

needles with an extra, individual dab of the stuff. The Vaseline both prevents

the needles from rusting and restrains their movements so as to preserve the

points.

Stock up with at least half a dozen of each size you want to use. These little

devils have a predictable tendency to get lost.

Palm

The common, Anglo-American style of hand-seaming palm (Fig. 10, foreground)

consists of a leather sling that is strapped around one's working hand,

performing the same function as a seamstress's thimble when entering a needle.

The butt of the threaded needle is placed within the circular, raised

"iron" section to brace against one of a number of indentations provided for

this purpose. A seaming palm may have more than a dozen small, shallow

indentations in its iron to take fine needles.

The roping palm with its thumb guard (Fig. 10, background), which has been

recommended in this book's introduction for its versatility, has only seven,

but more substantial, indentations. These do excellently in holding firmly the

gamut of needle sizes and, since a roping palm is far hardier than a

seaming palm, it is certainly to be preferred.

To prevent injury from an accidental slip of the needle, palms have a raised

buttress around the iron, and a pigskin "plate" stitched to the outside of

the leather sling. In a first-class palm, the iron's surface will be

perpendicular to the natural thrust of the needle to insure as safe an operation

as possible.

The best insurance, however, is to hold the needle correctly to begin with.

Steer it into one of the indentations in the iron with your ring finger and

make sure it remains in place by keeping the fingertip on it. Use the middle

fingertip and thumb to direct the needle, and the tip of the index finger as

sort of an advance scout, probing the canvas, making directional readjustments

to the tip of the needle, or bracing the canvas against the push of the needle.

You have to let go this excellent hold every time you

take a stitch, of course, but it should be resumed automatically as soon as the

needle is pulled through. The exception is when you want to wind the

twine around the thumb guard of a roping palm to heave tight on a stitch, in

which case the needle is held under the right-hand ring finger while the pull

is made.

Many of the sailmaker's palms commercially offered today—particularly seaming

palms—are not up to the old-time standard, consisting as they do of a flimsy

hunk of leather (or even plastic!) with a piece of tin haphazardly sewn on in

lieu of a bona fide iron. So when you shop for a palm, look for sturdy leather

construction. The leather in a properly-made roping palm will be %" thick, and

the plate at least half that in addition.

A well-made palm is a prized possession and a pleasure to work with, and ought

not to be underrated. The important thing when fitting a palm is that it doesn't

pinch at any place, such as around the base of the thumb, but fits snugly and

comfortably over the entire hand. If your local ship chandlery can't oblige, it

may be worthwhile to write to a reputable manufacturer such as Wm. Smith & Son

of Redditch, England, and order a Sailmaker's Roping Palm directly from them.

When you've found your ideal partner, rather than using the watchband buckle

usually provided for adjustment as shown in the seaming palm drawing, trim down

the ends of the bands so that they don't overlap and chafe your hand, and secure

with a neat, seamanlike, permanent seizing as in the roping palm.

The breaking-in of a new palm will take place over a period of time. Simply use

it to the extent that your own sweat, or hand moisture if you prefer, softens it

up. Eventually it will mold itself, then harden to an exact fit. If you obtain a

second-hand palm, or one which is generally a sorry fit, you may want to try

soaking the palm for a few hours in lukewarm water to make it more pliable and

thus more likely to readjust itself to your hand. I would hesitate to recommend

this with a really old palm, however, since the plate may have been secured with

animal glue. This will tend to run during a soaking, impairing the homogeneity

of the palm as well as discoloring it.

If treated with care and kept in a dry place, a good palm properly broken in

will be a joy forever. When I called by to see Everett Lohnes at his Lunenburg,

Nova Scotia, sail loft one September day, he pulled out half-a-dozen roping

palms which had belonged to sailmakers working a lifetime in that once busy

sailing port. One palm had been badly chipped around its iron, but the others

all were in perfect order, with smooth pigskin plates gleaming more richly than

the autumn sunlight in the harbor. And my own favorite palm was graciously

handed on to me long ago by an older colleague at his retirement.

Beeswax

If you've ever ventured into the glades of Sherwood Forest with Pyle as your

guide, you may remember catching a glimpse of Little John in the shade of the

greenwood tree, "rolling a stout bow string from long strands of hempen thread

... and rolling the cord upon his thigh." As he rubbed his new-made string with

yellow beeswax to fix the twist, Robin Hood, who had been gazing ruminatively at

his chief steward's doings, gave voice to an idea. The adventure that ensues is

the one where Little John, in the guise of a holy friar, makes bold to pick up

three pretty lasses at the Tuxford crossroads but I have to break off here to

point rather to Little John's prowess with the beeswax. His procedure, of waxing

doubled twine, then twisting it, and waxing it again to keep the twist in and

stabilize the cordage, is exactly how you should prepare a length of twine for

general seaming (for the twine itself, see next entry). The beeswax is a

fragrant pale yellow or amber commodity, which you can track down these days at

ship chandlers, sailmakers, and (in Europe at least) apothecaries.

Begin by taking a fathom of twine from your spool and threading it through a

needle. Double the twine (you now will have a 3' length) and, with a lump of

beeswax in your left hand, wax the twine by pulling it hard against the lump

Then twist the twine, making a counterclockwise turn with your left hand, and

a clockwise one with your right (Fig.12). A second and third waxing will keep

the twist in and help the twine to flow smoothly through canvas without

tangling.

If you require a stopper knot after threading and twisting the twine to prevent

the end from working loose as the seaming begins, make a loop as

shown in Fig. 13, pinch the twine juncture (arrow) between thumb and forefinger,

and pull the needle through. It is much better to sew in the end

as you go along, however.

Twine

Righthand twist, pre-waxed polyester is the flat, pliable twine most commonly

used for hand seaming. It is strong and very satisfactory to work with. But

for jobs with an ornamental aspect, such as sewn rings, the only real

alternative—round-lay polyester—will stand out much more distinctly, both on

account of its extra body and because of the more solidly white color.

Twine of the pre-waxed variety supposedly can be used without hand waxing, but

if you apply the customary rubdown to it previously discussed, you will

find that it holds the twist much better.

If you do a significant amount of hand seaming, buy your twine in a large spool

rather than in some overpriced smaller package.

In addition to multipurpose hand-seaming twine, you will want a spool of fine

polyester-and-cotton machine thread. Try to obtain the grade used by

sailmakers for light sail or spinnaker seams. The primary use for this fine but

strong thread is for whipping wire, where it will give a tight and hard

surface after waxing.

Sailmaker's Hook

As mentioned earlier, a canvas-piercing hook is indispensable in that it

provides an "extra hand" in any kind of hand-seaming work.

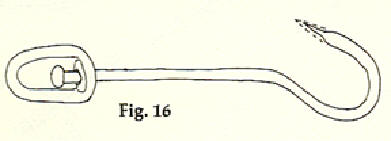

The most commonly used model consists of a 3" piece of round steel which has a

bronze swivel at one end for a spliced-in lanyard, and a pointed hook at

the other for insertion in the canvas (Fig. 16).

However, the point commercially supplied serves very poorly in this context,

since it is on the blunt side and difficult to press into the canvas. If really

drawn to a firm hold, it leaves a gaping hole or, quite possibly, a

rip.

To prevent such mishaps, you must sharpen the ends of these hooks with a file as

shown in the sketch (dotted line represents the original shape of the

point). The sharp end then allows the hook to enter canvas smoothly, while the

bulge prevents it from entering so far as to make a big hole or rip.

Prickers, Spikes and Fids

Spikes of iron, whale bone, or hardwood were among the earliest canvas- and

rope-working tools. They were used to pierce canvas for sewing and to pry

apart the strands of a rope for splicing. In time, these primitive tools were

developed into highly specialized instruments.

Piercing tools known as prickers (round or square section) and stabbers (with

the superior three-square section) have become sharp and effective but, for

the purpose of the ditty bag, rather cumbersome to carry. An obvious substitute

is our friend, the sharp knife. Pierce a star-shaped hole by taking three

strokes to the center, pry it open with a fid, and cut off the tatters with the

knife.

If you need to make a lot of holes, by far the best instrument is a regular hole

punch which cuts a neat, circular hole.

For piercing small holes—to make way for the needle in repairing boating

mocassins, for example (but even then, sewing through the rubber sole is

murderous)—I find an awl of the kind used in leather work the handiest tool. The

sharp end of this tool, as with any such pointed implement, should be protected

with a cork.

Rings Sewn rings and grommets

An expertly sewn ring is a thing of beauty, far superior in appearance, if not

necessarily in strength, to the hydraulically pressed eyelets that the modern

sail factory has to pass off as clew rings. Learning how to sew in a ring also

has the advantage that it can be done afloat if it becomes necessary to replace

a torn out clew or to provide an emergency reef point.

The proper fitting of a bronze ring requires some portable tooling, to wit: a

hole punch, a die, and a puncher (Fig. 32). To affix a ring, start by punching a

hole ten percent smaller than the diameter of the ring to be used. Thread a

needle with a fathom of twine, double and wax.

Now comes the difficult part of stitching on the ring without distorting or

misaligning the hole. The common and The trick here is to bring the inside of

the ring up flush with the very edge of the hole—at a point directly opposite to

where the first stitch is taken (Fig. 33:1). Fix the ring in this position

with your left thumb and forefinger as you lock the standing end of the twine

and start taking stitches with your right hand (Fig. 33:2).

Keeping a firm hold on the ring and canvas opposite to where stitches are taken,

continue to stitch just outside the ring, carefully spacing each needle entry

until the whole ring is covered sun-ray style, and the last stitch can be buried

der three or more of the initial stitches (Fig. 33:3).

Even spacing, apart from its visual value, will provide the best cushion as the

puncher and die are now brought together from opposite sides over the sewn-up

ring (Fig. 34). A few smart blows with a hammer or mallet are enough to force

the puncher into the die, thus bending round a thimble poised on the puncher to

encircle and reinforce the ring, partially covering the stitching.

Restraint must be exercised with the mallet blows to prevent the sharp edge of

the now-bent thimble from digging into the twine and parting it. (This, of

course, would very considerably lessen the holding power of the ring.) Also, the

inside perimeter of the die is very easily chipped by excess force.

It's a good idea to carry some medium-sized rings as ditty bag companions even

if you don't have a die and puncher aboard. The rings can be sewn in per above

as emergency clew rings, omitting the reinforcing thimble.

But short of a ring, you can still fashion a usable eye with only palm, needle,

and thread. Unlay one strand of laid rope (Fig. 35:1), preferably from

three-strand polyester for strength—though, particularly to practice

with, monofilament polythene is good, too. Cut the strand at a length equal to

three times the circumference of the proposed eye plus two or three inches for

finishing. Make a half-knot on the cut-off strand and draw it to the

predetermined dimensions of the eye (Fig. 35:2). Double the strand while

matching the twist (Fig. 35:3) and then, similarly, triple it. Finish with an

overhand knot where the two ends meet (Fig. 35:4).

Even an expertly laid rope grommet may not look symmetrical at this stage. To

improve it, slip it over the end of a fid and tap it down gently, as far as

it will go (Fig. 35:5, dotted line). See to it that the strand is uniformly

tensioned all around before cutting the ends. The cordage grommet will be sewn

on in exactly the same fashion as a bronze ring. Such a grommet will not be as

strong as a ring, and will distort considerably. But for a jury-rigged clew, it

will be perfectly sound.

Tape

The most useful tape for general wire serving and whipping work is no doubt the

common plastic tape which can be stretched to fit tight over almost

anything. But for serving a wire splice bristling with fish hooks, I prefer

insulating tape of the kind that is sticky on both sides and built up on a

fabric base. The texture makes it "fill" much better and absorb the hooks.

An altogether different type of tape—adhesive-backed nylon spinnaker cloth—is

commonly recommended for use in emergency sail repair. I would as soon use

less expensive broad masking tape, which holds on as well. However, generally

speaking, I would much rather stitch than tape a rip.

A really generally useful tape is Dacron webbing, which is dandy for

applications anywhere flexible, concentrated strength is needed.

Canvas

As with rope, synthetic fibers have elbowed out organic ones in the manufacture

of sailcloth proper. But since suppleness and heft is still desirable in canvas

work, cotton fibers can perform yeoman service if you want cloth for a ditty bag

or genuine canvas hammock. Besides, light cotton duck is much more pleasant to

sew than corresponding, harder, Dacron weave.

Dacron or Terylene cloth (the trade name for the polyester varies with the

country of origin) comes in a wide variety of surface finishes—from soft or

fairly soft unresinated weaves, to hard resinated sheets.

The smooth edge on either side of sailcloth panels is called selvedge.

Nylon spinnaker cloth, on account of its flightiness and stretch, is unsuitable

for hand seaming, but emergency repairs in it are quite feasible.

Just about all synthetic and cotton canvas used at sea is woven on commercial

looms where the longitudinal warp yarns (single or doubled) jump up and down to

admit the transverse fill (Fig. 44). When cutting canvas, try to cut cleanly

either along the warp, the fill, or the diagonal (bias). When cutting

to size with cotton, allow at least I" extra per foot of material for shrinkage.

The stretch characteristics of sailcloth depend on whether the stress is

directed along either threadline (less stretch) or else wise (more stretch). It

is therefore important that a patch is matched as closely as possible not only

to the existing cloth in terms of finish and weight, but also to the direction

of the yarns. Permanent repairs to performance sails should, of course, be

machine sewn to make the patching as discreet as possible.

The Processes

Perhaps the most gratifying aspect of sailing is that, despite advances in

materials and technology, its basics remain eternal. This is very much the case

with the ditty bag and its contents, which for centuries have survived virtually

intact. One reason is that from generation to generation, traditional

boat-keeping practices have proved both functional and attractive. Indeed, if

there is anything to be said in their disfavor, it is only that a certain amount

of skill and knowledge is required—which is not always the case with more modern

conveniences. Yet nothing says quite so much about kinship with sailboats and

the sea as the amount of extra effort the operator of a vessel has made to do

things right.

In the quest of learning to "do things right," we will begin with the essentials

of hand seaming. When mastered, these techniques will enable you to tackle any

canvas work with confidence, building up speed and a steady hand as you go

along. One of my early mentors perfected his skills hand-seaming huge tarpaulins

in W.W. II. But we'll do well first to turn to a smaller and surely more

interesting pursuit: that of making the ditty bag itself. And having run the

gamut of plain and fancy stitching, what better opportunity to finish off our

bag by introducing a few other seamanlike procedures that will employ the tools

to be put inside?

Making a Ditty Bag

The ditty bag (or its larger relative, the sea bag) used to be the first seaming

job an apprentice under sail would tackle. All the seams in nautical practice

were incorporated in fashioning these bags and the job, if properly learned,

prepared the novice for handling any seaming chore with complete confidence. It

therefore strikes me as the ideal project with which to start this section.

Besides, several other touches will be introduced which put a bit of cream on

it:

Six or more grommets have to be sewn into the hem of the bag to accommodate

lanyard splicings that come together in an eye at the top so the bag can be

suspended from a peg, or handled aloft with the top open to give easy access to

the tools. To close the bag, a turk's head, that most beloved of ornamental

knots, can be knotted below the eye for the utilitarian purpose of sliding up

and down on the bunched lanyards to open or close the bag at a touch of the

owner's hand. Moreover, in days of yore, the eye, and the handle pertaining to

it, were covered with natty rope work as an individualistic touch. The seams

were piped with brightly colored yarn to the same purpose and, among deep-sea

sailors with plenty of time on their hands, it was common practice to tuck a

strip of coarse canvas under the top selvedge seam, so that the warp yarns could

be pulled out and the remaining fill yarns knotted into some intricate design

right around the bag.

Seams

To put together the ditty bag, we'll execute the flat seam, round seam, and

tabling, with a later aside about running and roping stitches thrown in for good

measure. These happen to comprise all the basic stitches a hand-seaming sailor

uses. The majority never even feel the need to venture beyond the flat and the

round seam, which gives some idea of the versatility of these two seams. But a

variety of seams is worth at least a brief mention.

A flat seam (Fig. 45) is made from right to left or, in the vernacular (assuming

you're bench seaming), "away from the hook." The common variety—the double flat

seam (usually referred to simply as flat seam)—is used to join cloth pieces

which are overlapped and turned in at the edges to prevent fraying (a precaution

which is not necessary when joining selvedges or Dacron cloth cut with a

hot-knife). The drawing shows the work turned over, and the second seam being

put in.

To visualize better the seaming process, you may want to turn back to Fig. 2.

There, the first flat seam is being put in, with the work stretched out flat

between the sail hook and the seamer's left hand. To enable him to stretch the

upper and lower cloth adequately, the work has been doubled back to allow a

firm, left-hand hold, but the actual stitch area is flat, thus distinguishing it

from the more common round seam. As in virtually all hand seaming, the workpiece

rests over the knees.

A flat seam applied singly has application only in tabling; that is, when

turning over the edge of canvas for reinforcement and securing the doubled hem

with a stitch. When used for this purpose, the flat seam is referred to simply

as tabling.

The round seam (Fig. 46) is traditionally made from left to right, or "towards

the hook," and the bag, or whatever you're working with, is turned inside out

and the cloth is bent back in the seam area, so that the stitch is taken through

a protruding four-layer edge disappear when the work is returned right side to.

You can use round seam on the outside, too, with the ragged edges turned in, but

this is less common and referred to as single last round seam (Fig. 47).

Double last, another fairly rare stitch, denotes two round seams which are used to join canvas folded as for flat seaming (Fig. 48).

Endless argument once centered on whether the double flat or double last round

seam was the better way of joining sailcloth panels. Suffice it to say that for

seaming strength, you can rely on a round seam because of the tight stitching it

encourages while, for general seaming of overlapping canvas, a double flat seam

is better since the joint comes out flat and neat, without need for rubbing down

unsightly humps. The best rule of thumb I can think of is to use a round seam

for single seaming in utilitarian sewing, and a flat seam for double seams such

as in sail patching.

Nothing marks the accomplished palm-and-needle man better than a well-drawn,

uniformly spaced, row of stitching. Although essentially the same stitch, note

that the flat seam is stitched obliquely to form a zig-zag pattern, while the

round seam is taken more perpendicular to the work. The space reckoning is

usually calculated per needle length (figuring the length of a needle at 2l/2")-

Seven to nine stitches per needle length is the minimum required for a good

flat-seaming job. A round seam can be spaced more tightly, with a needle count

of up to 15, and no less than nine.

When joining canvas, it is a good idea to match up the two pieces before

starting the seam, and make a horizontal pencil mark across every other inch or

so. By keeping an eye on these marks as you go along, you'll be able to check

that you're aligning the two pieces evenly and correctly against one another.

It is also important to crease the work adequately. This process will be

discussed shortly.

Cutting Material to Size

For a pleasing end result, it is vital that the bag material (cotton duck canvas

of medium weight is probably the best choice) be marked up neatly and correctly

at the beginning. This should be done on the whole cloth, as the smaller the

piece, the less stability.

With an ordinary lead pencil, draw in the dimensions shown in Fig. 49, which

will yield a bag 14" high by 20" in circumference. The top of the bag is toward

the selvedge. Allow for a 1/2" tucking strip around the three other sides, as

these are likely to present fraying problems. The two 1" strips are designed to

overlap when sewing the bag together. A iy2" strip at the top of the bag will be

turned in to reinforce the hem.

To lay out the bottom piece, divide the circumference by six, which will give

the approximate radius, in this instance 3y3". Using this short-cut arithmetic,

you'll err on the large side by about 5 percent, but you'll want a bottom piece

which is a bit oversized to start with and only comes down to perfect size when

the last stitch has been drawn tight. (It must be borne in mind that the bottom

constitutes the lower cloth when being joined to the body of the bag with round

seam; the lower cloth contracts more than the upper when a seam is being put

in.)

Mark the center of the bottom piece on the canvas, insert a needle and use it as

a swivel for a twine sling of the same length as the radius. As seen in Fig. 50,

a pencil held in the sling will obviously project a perfect circle.

I would advise allowing a full inch outside this line for tucking, so as to

provide a wide margin for error in the bottom seaming. Cut with a sharp knife or

a pair of scissors.

Flat and Round Seams

Fold the 1/2" tucks on either side of the body piece in opposite directions as

shown in Fig. 51. The crease lines should be emphasized by rubbing. To this end,

hook up the upper right-hand corner of the canvas piece on the sail hook and

place it on your right knee, rubbing in a sharp crease with the back of your

knife blade as pictured in Fig. 52. Start by merely fixing the crease line with

short strokes of the blade taken towards you, then rub in a hard, permanent

crease by long, vigorous strokes in the same direction. When both tucks have

been rubbed down, the body of the bag is shaped into a cylinder (arrow, Fig.

51). The 1" ta-blings should now overlap as in Fig. 53.

Select a #15 or #16 needle, threaded with twine waxed and twisted in the

described fashion. Commence the first flat seam with your torso a quarter turn

to the left and your right elbow near your right hip, workpiece over your knees.

The canvas is held taut between your left hand and the sail hook (Fig. 54).

Since the workpiece is doubled back on your knee, one risks pushing down too

much on a stitch and inadvertently sewing the body of the bag into a figure

eight. The professional practice has always been to push the needle down through

both canvas layers. The needle is then withdrawn with some tension retained.

When the tip leaves the lower canvas, a quite audible "tic!" announces that

you're on the safe side and can proceed to guide the needle forward and up

through the upper canvas layers to take the stitch. This may be long in telling

but, with practice, the whole maneuver occupies only a fraction of a second.

Continue the seam, locking in the standing part as you go along, as shown in

Fig. 55.

Now let's assume the half-fathom of twine threatens to run out before you reach

the end of the first seam (unlikely, but the instructions of this particular bag

of tricks ought to include emergency countermeasures). Cut the twine a good inch

from the last stitch taken. Pull out the last part of the last stitch as

indicated in Fig. 56:1.

Thread and twist a new working length of twine and stitch through the hole just vacated. Here too, leave an inch of twine, twisting it together lightly with the end of the old twine. Fig. 56:2 should be helpful. Continue the seam with the twisted twine end under your left thumb, making sure the ends are locked securely under the first couple of stitches (Fig. 56:3). I have never known a seam joint to fail if executed in this manner. A round seam can be joined in the same way. When you get to the end of the seam, lock the end with a couple of back stitches as in Fig. 57, and cut. Turn the bag inside-out and proceed with a flat seam which is the twin of the one on the other side. Fig. 58 shows the start. When you get to the end of the seam, stitch back to lock the end just as in Fig. 57, before cutting.

With the bag still inside-out, turn up the l/2"-wide bottom strip as shown in

the upper part of Fig. 59, rubbing down the edge with the back of your knife

blade. Match it to the inner pencil circle on the bottom piece. Begin a round

seam, locking in the end (Fig. 60). Before starting the stitching, you might put

in a couple of "stoppers" (one is shown in Fig. 59) to make sure the alignment

is consistent.

Sew from left to right with careful, tight spacing—exaggerated in Fig. 61 to

show the progression. If you're lucky, you'll get a perfect fit on the first

try, but don't be discouraged if there is some discrepancy. Even an old hand has

to rely on experience and a keen eye to execute a faultless joint, stretching

one or the other cloths a bit extra on the run home in order to come out even.

When the round seam has been taken all around the bottom (Fig. 62), you can

either take a few more stitches overlapping the ones initially taken, or stitch

back as shown in the drawing. Cut the twine.

Running and Roping Seams

An alternative to the conventional fitting of the ditty bag bottom just

described, which will allow us to get into running and roping seams, is to fit a

laid rope ring (see Fig. 35) to the bottom. To facilitate this, the bottom piece

has to be sewn to the body in a different manner, with the bag rightside-out.

Reduce the tucking allowance to l/2" on the bottom piece. Insert it a full inch

into the body of the bag as shown in Fig. 63. Guided by the inner mark-up on the

bottom piece, put in a simple over-and-under running stitch to join it to the

body of the bag.

As in Fig. 64:1, fold the rim of the bag inward, rubbing it down firmly. The

ring will lay atop this fold. Make the ring from three-strand %" cordage to the

inside dimension of the bottom perimeter. Now the roping seam is employed. A

good way to conceive of the intent of this stitch is that it sews the rope to

the canvas, rather than the other way around. Direct a slightly blunt #14y2

needle precisely into the score of the rope and let it emerge just inside the

rim of the bag bottom opposite the next score, in effect stitching under one

strand as illustrated by Fig. 64:2. Pull tight firmly on every stitch to force

the canvas into the lay of the rope. Be sure to space the stitches so that the

twine is neatly buried in the consecutive scores. Sew all round and cut the

twine.

Having gained proficiency with the roping stitch, you'll be able to use it as a

stronger alternative to tabling wherever a canvas edge needs reinforcement.

Simply tuck over the edge, and join it to suitable cordage with a stitch as per

the above.

If you're called on to rope a sail, or to replace damaged bolt rope, proceed in

the same fashion, seaming from left to right, with the rope coil laid out

completely free of twist on your right-hand side. The amount of tautness in the

rope should not be overdone, since a slightly puckered luff, combined with an

appropriately elastic bolt rope, gives the necessary leeway for trim and

stretch.

Decorative Touches

Returning now to the ditty bag bottom with the round seam, we must next consider

the top rim of the bag, which can be finished either plainly or decoratively.

For the former, with the bag still inside-out, fold over the 1%" tabling

allowance, and rub the crease. Sew down the selvedge with a tabling stitch as

shown in Fig. 65. This seam, as pointed out before, is identical to a single

flat seam. When finished, turn the bag rightside-out.

If, on the other hand, you'd like some decorative tassel rather than a plain tucked rim, turn the work right side-to and crease the I1//' tabling outward, rather than inward. Under this run a 7" strip of coarse canvas. With a tabling stitch, sew this strip, the selvedge, and the inner part of the bag together. Fig. 66 shows the work in an advanced stage, where the 7" canvas strip has been slit at equal intervals in the course of becoming tassel.

The canvas strip should be cut out such that the warp yarns run horizontally

around the bag, since these are easier to pull out than the fill yarns. With

only the fill yarns remaining, any decorative knotting design can be effected,

the more common method being macramé or square-knotting. But before attacking

the warp yarns, remove at least half a dozen fill yarns from each of the slit

edges. This will reveal a finger hold when pulling at the warps.

For added personal touch, you may want to affix laid cordage rings or "grommets"

to attach a lanyard to. Six of these should be punched out with even spacing

along the rim. The buttonholing stitch shown in Fig. 66 will put a natty fringe

around the grommets if used in lieu of the previously described clew ring

stitch. For additional distinction, redouble your twine to make it four-ply.

This thicker twine will call for at least a #15 needle.

The Lanyard

We can now apply some of the processes described earlier, and learn some

valuable new ones, in the making of a lanyard for carrying our bag. Secure a 36"

length of :/2" or 3/4" twist and middle it—that is, double it in two. Put a flat

seizing on the eye thus formed.

Fig. 67 shows the techniques. Take a full seaming length of twine and, on a #12

to #14:/2 needle, thread and twist as usual. Place the standing part along the

doubled rope as displayed in Fig. 67:1 and commence taking turns. (For an eye

demanding more strength, such as might be used for rigging purposes, the two

ropes should first be stitched together firmly, but in this instance there is no

real need.)

Keep adding turns, heaving tight at every other turn, until the seizing is as

long as it is wide (Fig. 67:2). For frap-ping—i.e., snugging up—the seizing,

stitch under it as illustrated, then follow the black arrow through the eye and

back around the seizing. Take two or three more frapping turns, this time

tucking the needle under the bight of twine before coming back around (Fig.

67:3). As the needle comes back up between the rope tails, tension the frapping

turns of the twine by heaving tight with the roping palm or by one of the

methods described in the "Heaving" entry in Part I.

To secure the frapping turns and protect them and the entire seizing against

chafe, stitch round the turns repeatedly as shown in Fig. 67:4, and pull these

turns up tight to the left until the frapping is completely covered on both

sides of the seizing. Bring the working end through the eye to the top again,

and stitch through the seizing as in Fig. 67:5 to finish.

However, before cutting off the emerging end of the seizing cordage, you may

choose to continue with it to weave a coxcomb chafe cover around the eye, as

seen in Fig. 68. But first the novice might rehearse the process on a practice

bar (any old broomstick will do), shown in Figs. 68:1 and 68:2. In applying it

to the lanyard, take care to keep the comb well aligned around the perimeter of

the eye. Stitch under the seizing again to finish, and cut the twine close.

An even more fanciful option is to lay a star, diamond, or double-diamond knot

from the six unlaid lanyard strands, but the value is purely decorative and adds

a somewhat clumsy item to the bag. Nor could I in good faith recommend an

ornamental handle below the eye seizing as is sometimes done, for the same

reason.

But I definitely advocate slinging a turk's head round the un-laid strands, just

below the flat seizing. We will fashion a simple, three-lead, five-bight turk's

head, knotting it from a single length of cordage as shown in Fig. 69. (Again

the procedures are displayed on a broom handle or some such, though of course

the actual knot will be taken around the lanyard itself.)

The drawings should be self-explanatory from left to right. The necessity of

rotating the work a good quarter-turn at each step to allow for the proper tucks

is indicated by the arrows. A few further hints: In the center, one bight is

passed under another (shown by black arrow). In the fourth drawing, the working

end is tucked in beside the standing part, and from there it's simply a matter

of doubling and finally tripling the standing part. The last drawing shows the

completed knot, its ends cut flush. As with any turk's head, pass the earlier

leads loosely, since even then by the time the third lead is underway the knot

will have tightened to the extent where the last few tucks will have to be made

with assistance of a Swedish fid. Additionally, moderation should be exercised

for this particular application so that the completed head will slide freely

along the bunched lanyard strands. Incidentally, any knot in this decorative

category may be enhanced by later painting or inking one lead in a contrasting

color.

But let's not forget the other end of those lanyard strands, which remain to be

secured to the six rope grom-mets. To do this, measure off the last 3" of each

strand end, and tuck it through the hole and back up against the standing part.

Seize over firmly with a threaded length of twine in the manner shown in Fig. 76

a few pages hence. Arranged thus, the ditty bag can be taken aloft and suspended

open, with tools handy.